Crack Isolation Membrane & Removal in Phoenix, Arizona

Many times, depending on sub-floor conditions, we use Hydroment Ultraset Urethane for crack isolation. In our opinion, there is no better crack isolation product that performs better. If you have a badly cracked concrete subfloor and need to figure a way out to prevent cracking of Stone, Tile, or Porcelain, this is the correct crack isolation product to use before adhering to the flooring. This project was the worst of the worst and IS NOT typical of what we run into. In the picture you can see a very large crack that we had to grind flat. What you can’t see in this picture is all the smaller cracks that ran throughout the project. That is why we are fully covering the concrete floor. Without a product like this, this customer’s travertine would begin cracking in a relatively short amount of time.

When cracks are very straight we choose to use another type of product called Flex Guard. But, when cracks are crooked and wavy the quickest and most effective way of crack isolation is to handle this with Hydroment Ultraset Urethane. Used properly, I can guarantee that cracking from horizontal movement will never occur in the flooring.

Get a Free Quote

Finding the Crack Isolation Membrane

Nothing is worse than one of those surprise additional charges that occur after you have committed to a contractor’s estimate via their contract. That is why at Arizona Home Floors, we strive to be as informative and upfront about our work and costs as possible. With that in mind, you should know that our crew cannot predict the presence of a crack membrane when performing an estimate.

We can’t see it until actually removing your floor tile. We can measure an entire home in advance, but we are not able to find a crack isolation membrane under the existing tile until we remove the tile from your subfloor.

Speak with an Expert

What is Crack Membrane?

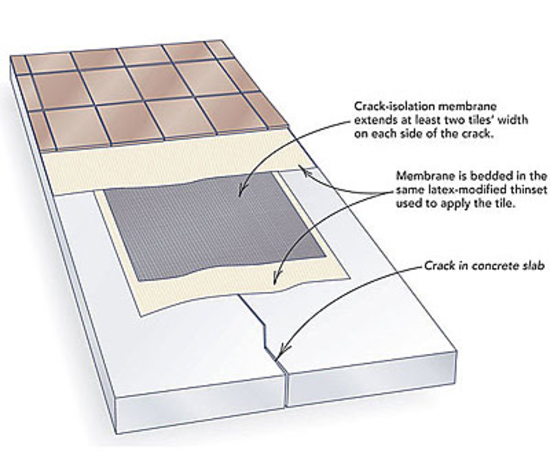

Just what is a crack membrane? It’s an isolastic material designed to prevent pre-existing cracks in concrete from telegraphing through the tile or stone installed. If the movement of the concrete slab occurs, the crack membrane will shift the movement over to a “grout joint” close to where the crack occurs in the slab.

The reason for this is that it’s easier to repair a cracked grout joint than it is to repair a cracked tile. Since most subfloors are made with concrete, as the initial pour begins to harden, it begins to shrink as the water leaves the concrete, a process known as ‘drying shrinkage’.

Here is an illustrated picture of how it's installed:

Here is some green crack membrane we pulled out of a recent job, you can see some of the tile and thin-set still attached.

How Cracks Come About

This can cause the slab to crack, especially at control joints, which were pre-planned into the concrete slab anyhow. Additional problems with cracking can be caused by poor soil preparation and/or weak over-watered concrete. These problems may also cause cracks or cracking to randomly develop throughout the slab. Even if control joints are installed properly, how your tile is laid may not align with the locations of joints and in order to prevent cracks from transferring upward to the tiles or along the grout lines, it will require installation of a crack isolation membrane.

The membrane covers the crack and allows the bonded thin-set and tiles to ‘float’ over the cracks and joints, reducing the chance of damage to your tile flooring when the concrete slab moves. It is impossible to know if there is a crack membrane on your floor until the tiles and thinset have been removed completely. If you are replacing your old flooring, the old crack membrane has to be removed as well before your new flooring is installed.

Removing Old Crack Membrane Before Your New Floor is Installed

This is not an easy process as it is similar to a very thick and sticky Duct Tape and typically has CONSIDERABLY more adhesion. In fact, for some types of crack membrane installed over weak and/or soft concrete, it is not at all unusual for the crack membrane to be so well bonded as to tear away the entire layer of concrete it has been installed over; if trying to physically pull it from the floor.

The DustRam® System is the Solution

With the DustRam® System, we can take a very slow and tedious process and make it much faster and more efficient, while minimizing the damage typically seen from using power scrapers or demolition hammers to remove the crack membrane.

The installer of your new flooring will have a superior surface to apply the new crack membrane before installing your new floor. There is an additional charge when and ONLY IF we encounter a crack membrane that needs to be removed.

We do not automatically include Crack Membrane Removal Charges in our Estimate and will only charge you if it is there. Please watch our videos to see how the DustRam® equipment removes both Thinset and the Crack Membrane under it.